Material Selection and Requirements in Product Design

Carlos Rodriguez | August 11, 2025

Read time: 6 minutes

"Material selection involves seeking the best match between the property profiles of the materials and that required by the design. Good design works, excellent design gives pleasure".

-Michael Ashby

The selection of materials is a crucial decision in the product design process, which consists of three stages: Concept Design, Embodiment, and Detail. This process begins with identifying market needs and the voice of the customer (VoC) and concludes with detailed product specifications. Each stage has a specific focus regarding material selection, addressing individual requirements and parameters, as well as considerations such as performance, manufacturability, usability, aesthetics, cost, and sustainability. Effective product design integrates engineering aspects (technical design) with elements of aesthetics, usability, and customer satisfaction (industrial design).

When selecting materials, product designers must assess their specific properties alongside the manufacturing or transformation processes needed to create the desired forms. Material properties are typically categorized into mechanical, thermal, electrical, chemical, and optical properties (Smith, 2024). The relevance of each property varies depending on the specific application of the product design. This essay will examine the rationale behind material selection and propose specific tools to assist designers and engineers in making informed decisions. As Ashby and Johnson (2010) noted, not only does "form follow function," but "form follows material," indicating that the unique properties of materials can either support or hinder the fulfillment of design requirements across technical, aesthetic, sustainability, and economic dimensions.

Considerations in material selection

Product and engineering designers consider several key factors when selecting materials:

- Functional Requirements: These are categorized into various domains:

- Mechanical (strength, toughness, stiffness, hardness, wear resistance)

- Thermal (conductivity, thermal expansion, melting point, insulation needs)

- Electrical (conductivity, resistivity, dielectric properties)

- Optical (transparency, reflectivity, color consistency)

- Chemical (corrosion resistance, chemical inertness)

- Manufacturability Requirements: This includes compatibility with manufacturing processes (machining, molding, casting, 3D printing), ease of fabrication (formability), and methods for joining and assembly (welding, adhesives, fasteners).

- Aesthetic and Ergonomic Requirements: Considerations include surface qualities (finishing, texture, appearance), tactile characteristics (soft touch versus rigidity), and coatability (ability to accept coatings, colors, or finishes).

- Economic and Cost Requirements: Factors encompass material costs (cost per unit), processing expenses (machining, forming), and lifecycle costs (maintenance, durability, recyclability, reusability).

- Sustainability and Environmental Requirements: This includes assessing environmental impact (carbon footprint, contamination), circularity (availability of renewable, recyclable materials), and compliance with regulations (safety and security standards).

- Lightweighting and Efficiency: Considerations focus on weight (portability, shipping costs) and maintaining structural integrity.

- Performance Under Stress-Strain: Materials must withstand various stresses, including tension, compression, torsion, and temperature extremes.

- Smart and Intelligent Behavior Requirements: Materials may need to exhibit responsiveness and adaptability to temperature changes, electric fields, and pressure, such as Shape Memory Alloys (SMAs), piezoelectric materials, biocompatible options, and smart textiles.

Materials selection process

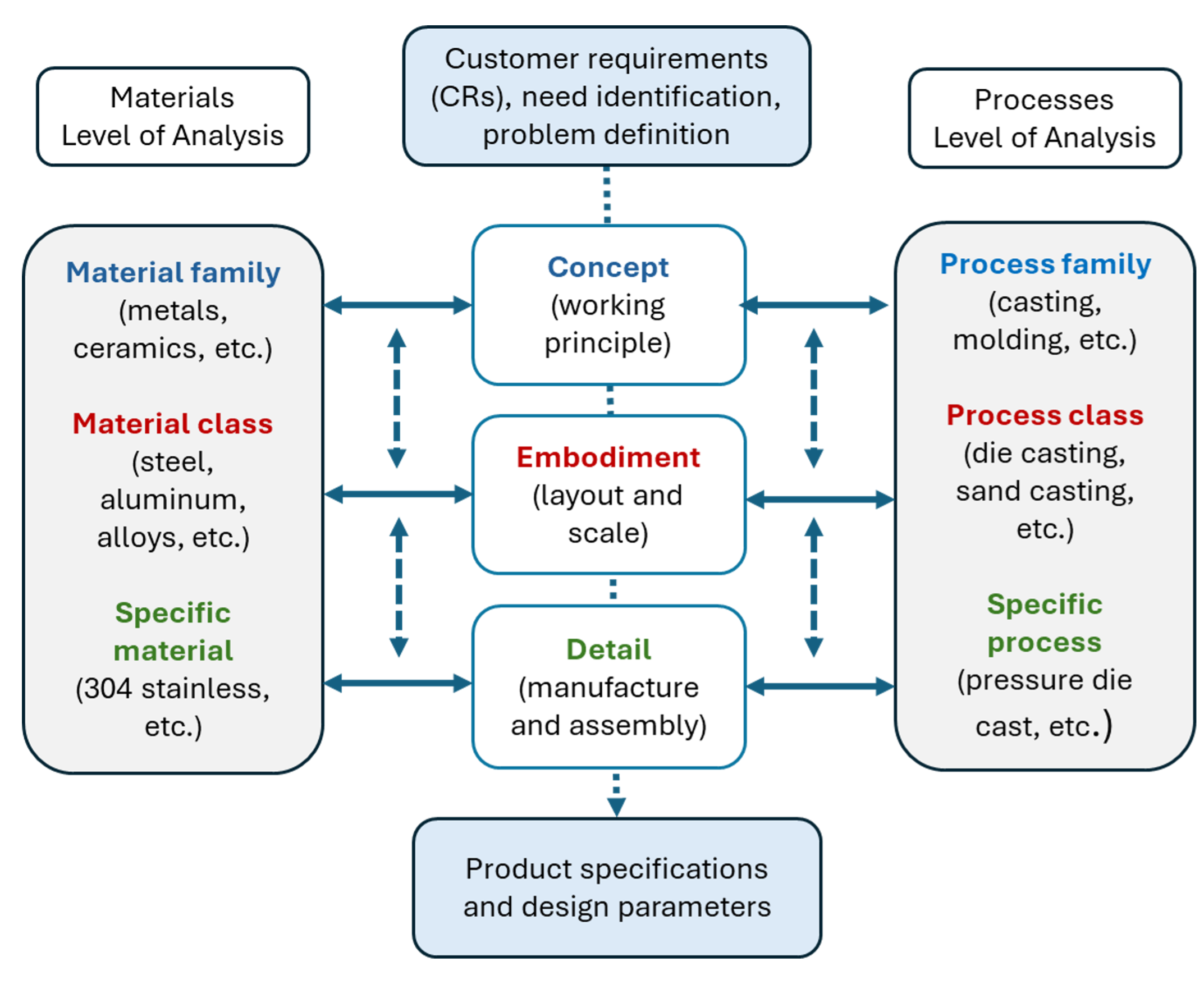

Product and engineering designers adhere to the process outlined in Figure 1. The material selection begins with identifying the material family, then progresses to evaluating the class level, ultimately leading to the selection of a specific material for the design. Concurrently, the process requirements are analyzed, starting from the general family process, moving to the class, and culminating in the final process selection. At each stage, the information regarding materials varies in breadth, precision, and technical specifications.

Figure 1: The Design Flow Chart

Source: The author, adapted from (Ashby et al., 2019)

Materials selection process

Product designers have a wide variety of tools and methodologies that assist in material selection for each of the design stages indicated in Figure 1: Concept definition, Embodiment, and Detail.

Concept Stage

Concept Stage

The design process engages in broad exploration. The goal is to identify feasible material families that meet all general customer requirements, function analysis, and component behavior.

Some of the available tools are:

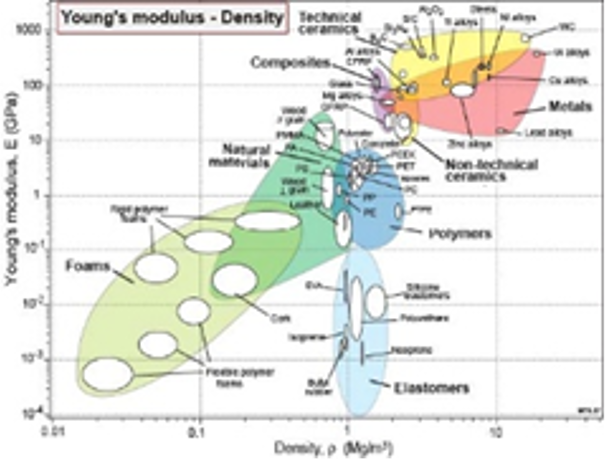

- Ashby Material Selection Charts (Strength vs. Density, Stiffness vs. Cost charts).

- Material Families Database (e.g., CES EduPack/Granta EduPack).

- Morphological Charts for exploring materials and forms.

- Benchmarking & Analogical Reasoning (examining similar products)

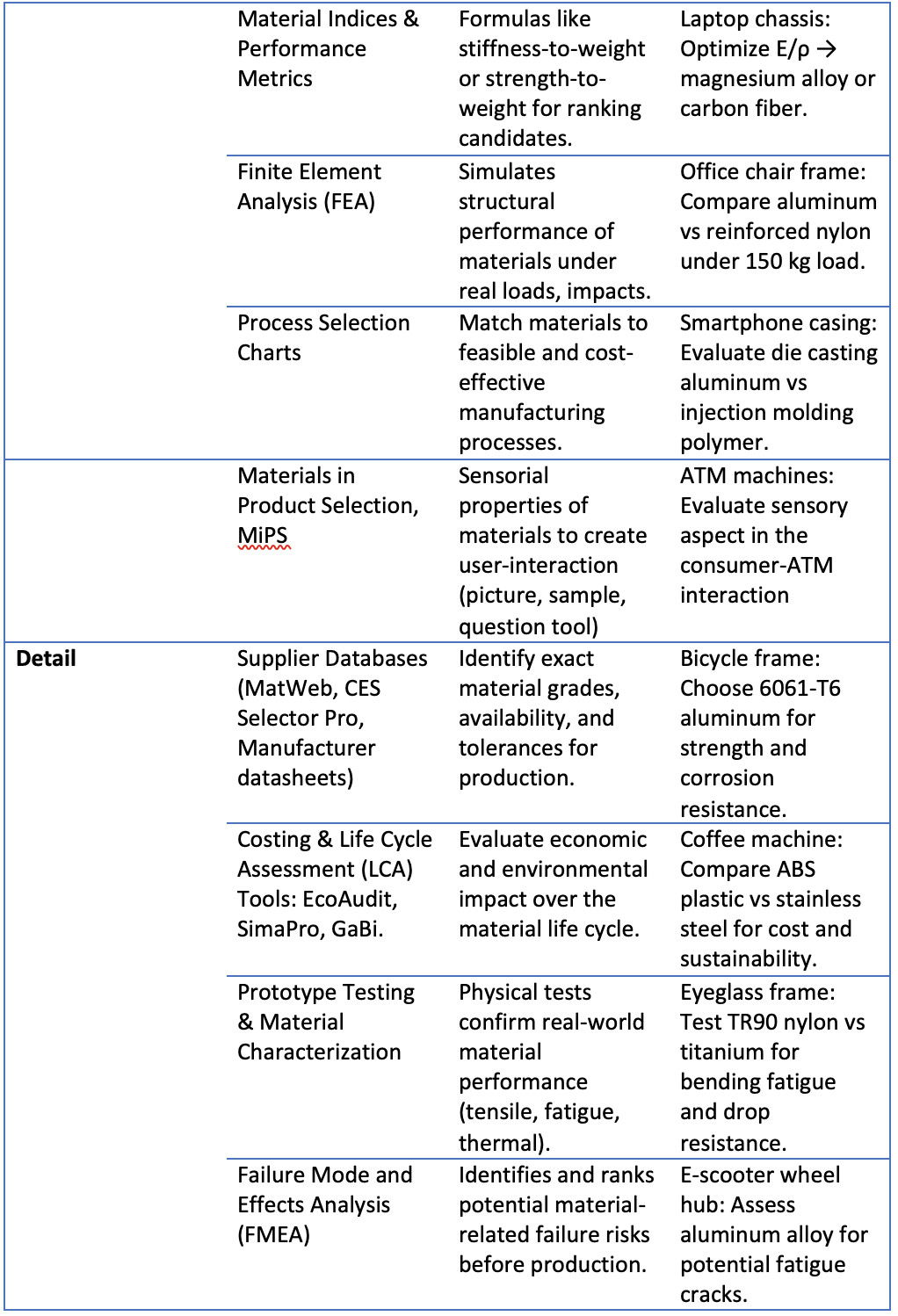

Embodiment Stage

The design process involves refining functions, technical specifications, behavioral, usage, and operation of product components. The goal is to narrow down to specific materials that meet functional and manufacturing constraints.

Some of the available tools are:

- Material Property Tables (standards like ASTM, ISO).

- Materials in Product Selection (user-product interaction specifications)

- Material Indices & Performance Metrics (e.g., strength-to-weight ratio, thermal conductivity versus cost, durability against environmental degradation, stiffness-to-weight).

- Finite Element Analysis (FEA) to test stress, deformation, and thermal behavior.

- Process Selection Charts (to check manufacturability).

Detail Design Stage

The design process focuses on the final selection and verification of grade, form, cost, and feasibility of the material selection.

Some available tools are:

- Supplier Databases (MatWeb, CES Selector professional, manufacturers’ datasheets)

- Costing and Life Cycle Assessment (LCA) Tools (EcoAudit, SimaPro, GaBi).

- Prototype Testing & Material Characterization (tensile, fatigue, thermal tests).

- Failure Mode and Effects Analysis (FMEA) for risk assessment.

Table 1 summarizes the tools used in the Concept, Embodiment, and Design Detail stages of the product design to assist in material selection. A description of each tool is provided with selected examples.

Table 1: Material Selection Tools across Product Design Stages

Source: The author

Conclusion

The materials selection process is a crucial aspect of product and engineering design. Product managers should possess a solid understanding of the various materials available, along with their specific properties and behaviors. Choosing the right material significantly affects the product’s performance, functionality, durability, cost, and sustainability. This selection process begins with a clear comprehension of customer needs and requirements, followed by identifying suitable materials, ranking them through screening, and conducting testing and prototyping.

References and Further Reading

Ashby, M. and Johnson, K. (2003), "The art of materials selection", Materials Today, Vol. 6 No. 12, pp. 24-35, doi: https://doi.org/10.1016/S1369-7021(03)01223-9.

Ashby, M., Shercliff, H. and Cebon, D. (2019), Materials: Engineering, science, processing and design, Butterworth-Heinemann, Elsevier, United Kingdom.

Ashby, M. F. and Johnson, K. (2010), Materials and design: The art and science of material selection in product design, Elsevier Science.

Ramalhete, P. S., Senos, A. M. R. and Aguiar, C. (2010), "Digital tools for material selection in product design", Materials & Design (1980-2015), Vol. 31 No. 5, pp. 2275-2287, doi: https://doi.org/10.1016/j.matdes.2009.12.013.

Smith, J. (2024), Materials science step by step: Principles and fundamentals of materials for engineering & design, TagVault Publishing.

van Kesteren, I. (2008), "Product designers’ information needs in materials selection", Materials & Design, Vol. 29 No. 1, pp. 133-145, doi: https://doi.org/10.1016/j.matdes.2006.11.008.

van Kesteren, I., Jan Stappers, P. and de Bruijn, S. (2007), Materials in products selection: Tools for including user-interaction in materials selection.

Zarandi, M., Mansour, S., Hosseinijou, s. a. and Avazbeigi, M. (2011), "A material selection methodology and expert system for sustainable product design", International Journal of Advanced Manufacturing Technology - INT J ADV MANUF TECHNOL, Vol. 57, doi: 10.1007/s00170-011-3362-y.

About the Author

Carlos Rodriguez

Carlos M Rodriguez is an Associate Professor of Marketing and Quantitative Methods and Director of the Center for the Study of Innovation Management, CSIM in the College of Business, Delaware State University, USA. His publications have appeared in the Journal of Business Research, Journal of Business to Business Marketing, Journal of International Marketing, International Marketing Review, Management Decision, International Journal of Business and Social Sciences, Journal of Business and Leadership, and Journal of Higher Education Research & Development among others and several conference proceedings. Currently, he serves in the editorial board of several journals. His research interests are in the areas of entrepreneurship and strategic capabilities, luxury branding and experiences, product design and new product development teams, and relationship marketing. He recently published the book entitled Product Design and Innovation: Analytics for Decision Making centered in the design techniques and methodologies vital to the product design process. He is engaged in several international educational, research, and academic projects, as well, as, international professional activities.